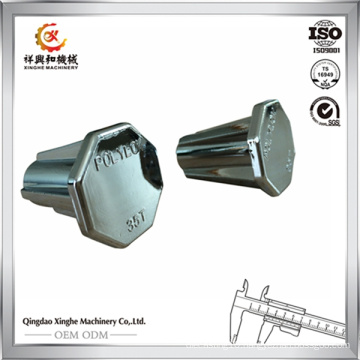

Custom Die Casting Mould Die Casting Parts Die Casting Aluminium

Basic Info

Model No.: Custom die casting parts die casting aluminium

Product Description

Model NO.: Custom Die Casting Parts Die Casting aluminium Die Casting Method: Soluble Die Casting Machining: CNC Machining Surface Preparation: Polishing Tolerance Grade: 4 Name: ADC1 Aluminium Die Casting Type: Drilling, Tapping, Milling, Laser Machining Strict QC: Reliable Quality with Precision 0.05 Factory Price: Available Dlivery Time: 30 Days After Payment Transport Package: 1.Polybag , Carton, 2.Pallet or Container, 3custom Origin: Qingdao, Shandong, China Die Casting Machine Type: Cold Chamber Die Casting Machine Application: Hardware Material: Aluminum Alloy Pressure Chamber Structure: Vertical Certification: SGS, CE, RoHS, ISO 9001:2000, ISO 9001:2008, ISO 9001:2008, AISI, CE, Ieo, SGS Technology: Cnc Machining/Turning Surface Finish: Polishing, Anodising, Powder Coating etc Size and Length: Sandard or Custom Require Warranty: 20 Years Trademark: Adc1 Aluminium Die Casting Specification: ISO 9001: 2008, AISI, CE, IEO, SGS HS Code: 8460190000 Custom die casting mould die Casting Parts die casting aluminium

1). We are ISO9001: 2008 certified, BSI Kitemarked, TUV certified, SGS certified and NF certified.

2). SYI products are widely used in many fields. Readable software includes PRO/E, auto CAD, UG and solid works 2008 flow analysis. You might also get suggestions from us to help you save time.

3). Processes:

Die Casting

4). Material:

A) A380/AL383/AL413

B) ADC10/ADC12/ADC1

C) Zamak 3/Zamak 5

5). Surface treatment

A) Anodizing under various color requirements

B) Powder coating

6). Equipment:

A) 88T-1500T Die Casting Machine

B) CNC machining centre

C) Various surface treatment available

D) Min. Hole dia: 1 mm

Min. Wall thickness: 1.5 mm

Min. Tolerance: ± 0.1 mm

Weight of the largest die cast part can up to 6Kgs

7). Inspection:

A) Foundry in-house

B) Third party inspection available upon request

8). Packing:

A) Wooden Pallet

B) Plywood Pallet

C) Steel Pallet

D) As per customers' requirements

9). Guarantee:

All of SYI casting products are guaranteed with smooth and free from sand holes, blow holes, distortion or any other defects.

10). CAD/OEM service is available.

More information is available upon receipt of your enquiry.

You will get our quick reply!

Contact us if you need more details on Die Casting Aluminium. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Die Casting Parts、Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1). We are ISO9001: 2008 certified, BSI Kitemarked, TUV certified, SGS certified and NF certified.

2). SYI products are widely used in many fields. Readable software includes PRO/E, auto CAD, UG and solid works 2008 flow analysis. You might also get suggestions from us to help you save time.

3). Processes:

Die Casting

4). Material:

A) A380/AL383/AL413

B) ADC10/ADC12/ADC1

C) Zamak 3/Zamak 5

5). Surface treatment

A) Anodizing under various color requirements

B) Powder coating

6). Equipment:

A) 88T-1500T Die Casting Machine

B) CNC machining centre

C) Various surface treatment available

D) Min. Hole dia: 1 mm

Min. Wall thickness: 1.5 mm

Min. Tolerance: ± 0.1 mm

Weight of the largest die cast part can up to 6Kgs

7). Inspection:

A) Foundry in-house

B) Third party inspection available upon request

8). Packing:

A) Wooden Pallet

B) Plywood Pallet

C) Steel Pallet

D) As per customers' requirements

9). Guarantee:

All of SYI casting products are guaranteed with smooth and free from sand holes, blow holes, distortion or any other defects.

10). CAD/OEM service is available.

More information is available upon receipt of your enquiry.

You will get our quick reply!

| Drawing | PDF, STP, DWG, CAD. |

| Production Process | Die casting, Deburring, Drilling holes, Tapping, CNC Machining and Assembly |

| Surface Treatment | Sand blasting, Tumbling, Powder coating, Wet painting, Painting, Anodizing and Polishing |

| Die casting materials | aluminum alloy, A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104 and ZL107 |

| Company Advantage | 1) ODM&OEM according to your drawing. |

| 2) Small quantity with mixed items is also available | |

| 3) High Precision, New Technology, Competitive Price for Aluminum Die Casting | |

| 4) Advanced die casting machines available. | |

| 5) All kinds of facility, CNC machining, turning, milling, tapping, drilling, polishing, punching, etc... | |

| 6) Competitive Prices, Excellent Service, and Good Lead Time. |

Product Categories : Casting Molds > Sand Casting

Premium Related Products

Other Products

Hot Products

New design fashion low price door handles with locksNew arrival 2016 custom Aluminum Die Casting Gear HousingAluminum Alloy casted LED Light EnclosureAntenna Mountanchor rodsDrain Parts can be used for bathroom sink and floorAluminum and Zinc Die Casting partDie Casting aluminum Enclosure/die casting moldCooling block2015 made in China customized die casting aluminum wheelCE certificated powder coating Electrical Cabinet/sheet metal formingPlastic Float BallSteel hanger, apron rack,Medical hangersFull suspection steel belt wheel 2015Toughened glassRotational Molded Boat