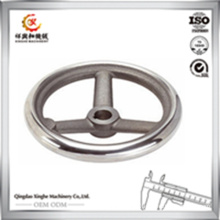

Investment Casting Suppliers with Stainless Steel Casting

Basic Info

Model No.: customized

Product Description

Model NO.: customized Process: Investment Casting Application: Agricultural Machinery Parts Surface Preparation: Polishing Machining Tolerance: +/-0.15mm Certification: ISO 9001:2008 Quality Certification: ISO 9001:2008, AISI, CE, Ieo, SGS Warranty: 20 Years Machining: Tapping,Milling, Grinding Post-Process: Heat Treatment Specification: From 50kg to 250kg HS Code: 7307190000 Casting Method: Thermal Gravity Casting Molding Technics: Gravity Casting Material: Carbon Steel Surface Roughness: Ra3.2 Standard: AISI Name: Investment Casting Suppliers Roughness: 0.005 Technology: Investment Casting, Machining Surface Finish: Polishing, Anodising, Powder Coating etc Trademark: Auto Parts Investment Casting Origin: Qingdao Shandong

1. Product Name: Investment Casting

2. Features: Conversion of Weldments, Other Casting Processes, Fabrications, Forgings and Assemblies to Investment Castings

3. Material: Parts can be cast in our very wide range of materials, including: Alloy steel, Carbon steel, Copper based alloy, Stainless steel, Aluminum alloys & zinc, Heat resisting steels, Alloys for magnetic use, etc.

4. Technique: Precision Casting, Investment casting, Lost wax casting, Stainless steel precision casting

5. Process: Die making & wax pattern, Assembly of wax pattern, Dipping the assembly into Silica Sol slurry, Sand-spraying & shell built, Dewax & firing, Pouring the metal, Shell & part removal, Finishing & secondary operations

6. Rapid Prototyping: Quick, easy and economical, can take your CAD designs and turn them directly into a pattern. Metal prototypes produced with the latest technology in 3D modeling and the precision of the investment casting prototype process

7. Finish: Carefully fettled, blasted & heat-treated; Grinding, machining, polishing, chrome / zinc / nickel plating or painting

8. Heat Treatment: Quenching, Normalizing, Tempering, Annealing, etc.

9. Capabilities:

1) Precision casting capabilities: Rapid Prototyping, Vacuum Melting Furnace, Vacuum Dewaxing System

2) Machining equipment: Horizontal Machining Centers, CNC Machine (Horizon, Vertical & Clear)

3) Inspection equipment: Spectrometer; Coordinate Measuring Machine (CMM); Non-destructive testing

4) Drawing capacity: PDF, Auto CAD, Solid work, JPG, Proe

Contact us if you need more details on Investment Casting Suppliers. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Investment Casting、Casting Supplier. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Product Name: Investment Casting

2. Features: Conversion of Weldments, Other Casting Processes, Fabrications, Forgings and Assemblies to Investment Castings

3. Material: Parts can be cast in our very wide range of materials, including: Alloy steel, Carbon steel, Copper based alloy, Stainless steel, Aluminum alloys & zinc, Heat resisting steels, Alloys for magnetic use, etc.

4. Technique: Precision Casting, Investment casting, Lost wax casting, Stainless steel precision casting

5. Process: Die making & wax pattern, Assembly of wax pattern, Dipping the assembly into Silica Sol slurry, Sand-spraying & shell built, Dewax & firing, Pouring the metal, Shell & part removal, Finishing & secondary operations

6. Rapid Prototyping: Quick, easy and economical, can take your CAD designs and turn them directly into a pattern. Metal prototypes produced with the latest technology in 3D modeling and the precision of the investment casting prototype process

7. Finish: Carefully fettled, blasted & heat-treated; Grinding, machining, polishing, chrome / zinc / nickel plating or painting

8. Heat Treatment: Quenching, Normalizing, Tempering, Annealing, etc.

9. Capabilities:

1) Precision casting capabilities: Rapid Prototyping, Vacuum Melting Furnace, Vacuum Dewaxing System

2) Machining equipment: Horizontal Machining Centers, CNC Machine (Horizon, Vertical & Clear)

3) Inspection equipment: Spectrometer; Coordinate Measuring Machine (CMM); Non-destructive testing

4) Drawing capacity: PDF, Auto CAD, Solid work, JPG, Proe

| PROCESS | MATERIAL | STANDARD | |

| SAND CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| INVESTMENT CASTING | Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| Forging | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| Stamping MACHINING | STAMPING MACHINING | All metal material | |

Product Categories : Casting Molds > Precision Casting

Premium Related Products

Other Products

Hot Products

New design fashion low price door handles with locksNew arrival 2016 custom Aluminum Die Casting Gear HousingAluminum Alloy casted LED Light EnclosureAntenna Mountanchor rodsDrain Parts can be used for bathroom sink and floorAluminum and Zinc Die Casting partDie Casting aluminum Enclosure/die casting moldCooling block2015 made in China customized die casting aluminum wheelCE certificated powder coating Electrical Cabinet/sheet metal formingPlastic Float BallSteel hanger, apron rack,Medical hangersFull suspection steel belt wheel 2015Toughened glassRotational Molded Boat