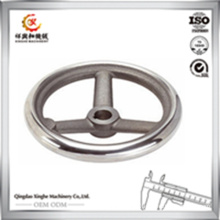

OEM Cast Iron Casting Construction Parts Iron Casting

Basic Info

Model No.: OEM iron casting

Product Description

Model NO.: OEM iron casting Casting Method: pressure Crystallization Application: Agricultural Machinery Parts Material: Iron Surface Roughness: Ra0.4 Certification: SGS, CE, RoHS, ISO 9001:2000, ISO 9001:2008 OEM and ODM: 100% Technology: Sand Casting Color: Nature or as Request Welcome: Drawing and Samples Packaging: as Customers′ Requirement Transport Package: Carbon Box Then Wooden Crate Origin: Qingdao Type: Clay Dry Sand Sand Core Type: Sodium Silicate Sand Core Machining: CNC Machining Surface Treatment: Electroplating Standard: ASME Product Name: OEM Construction Parts Iron Casting Best Products: Best Price Casting: Sand Casting Die Casting Precision Casting Tolerance: as Drawings Delivery Time: 30 Days After Payment Trademark: XH Specification: Grey iron sand Casting Parts HS Code: 7325101000 OEM cast iron casting construction parts iron casting

Our products:

1. Cast iron(ASTM-A48, Class 25-45 gray iron casting, ASTM ductile iron casting

2. Cast steel (carbon casting: Allow casting, stainless steel castings)

3. Cast aluminum ( ASTM 356T6; 380)

A. The Forging foundries produce: Forgings and stampings (all kinds of materials)

B. The machining foundries: We own stuitable size of Lathe Milling machine, Grinding machine, Planer and so on

4. Cast brass(Brass casting and Bronze castings).

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Produce will be based on customers' drawing, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, SolidWorks, etc.

Casting capability: 200-500 tons / per month.

Machining process: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and working hard employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Hope we can build good cooperation with you.

Contact us if you need more details on Iron Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cast Iron Casting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our products:

1. Cast iron(ASTM-A48, Class 25-45 gray iron casting, ASTM ductile iron casting

2. Cast steel (carbon casting: Allow casting, stainless steel castings)

3. Cast aluminum ( ASTM 356T6; 380)

A. The Forging foundries produce: Forgings and stampings (all kinds of materials)

B. The machining foundries: We own stuitable size of Lathe Milling machine, Grinding machine, Planer and so on

4. Cast brass(Brass casting and Bronze castings).

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Produce will be based on customers' drawing, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, SolidWorks, etc.

Casting capability: 200-500 tons / per month.

Machining process: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and working hard employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Hope we can build good cooperation with you.

| PROCESS | MATERIAL | STANDARD | |

| Sand Casting | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon, Steel, Aluminum, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| Investment casting | Sodium Silicone (Water glass) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| Forging | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| Stamping Machining | Stamping Machining | All metal material | |

| Surface finish process | Shot blast, chromate plating, power coated and anodizing | ||

| machining | Turning and cutting, milling, grinding, drilling, reaming and threading | ||

Contact us if you need more details on Iron Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cast Iron Casting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Casting Molds > Sand Casting

Premium Related Products

Other Products

Hot Products

New design fashion low price door handles with locksNew arrival 2016 custom Aluminum Die Casting Gear HousingAluminum Alloy casted LED Light EnclosureAntenna Mountanchor rodsDrain Parts can be used for bathroom sink and floorAluminum and Zinc Die Casting partDie Casting aluminum Enclosure/die casting moldCooling block2015 made in China customized die casting aluminum wheelCE certificated powder coating Electrical Cabinet/sheet metal formingPlastic Float BallSteel hanger, apron rack,Medical hangersFull suspection steel belt wheel 2015Toughened glassRotational Molded Boat