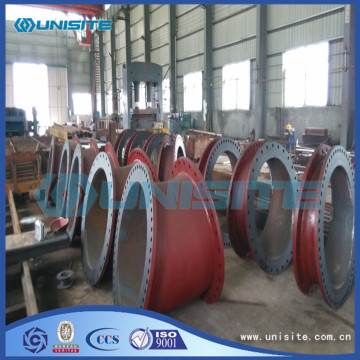

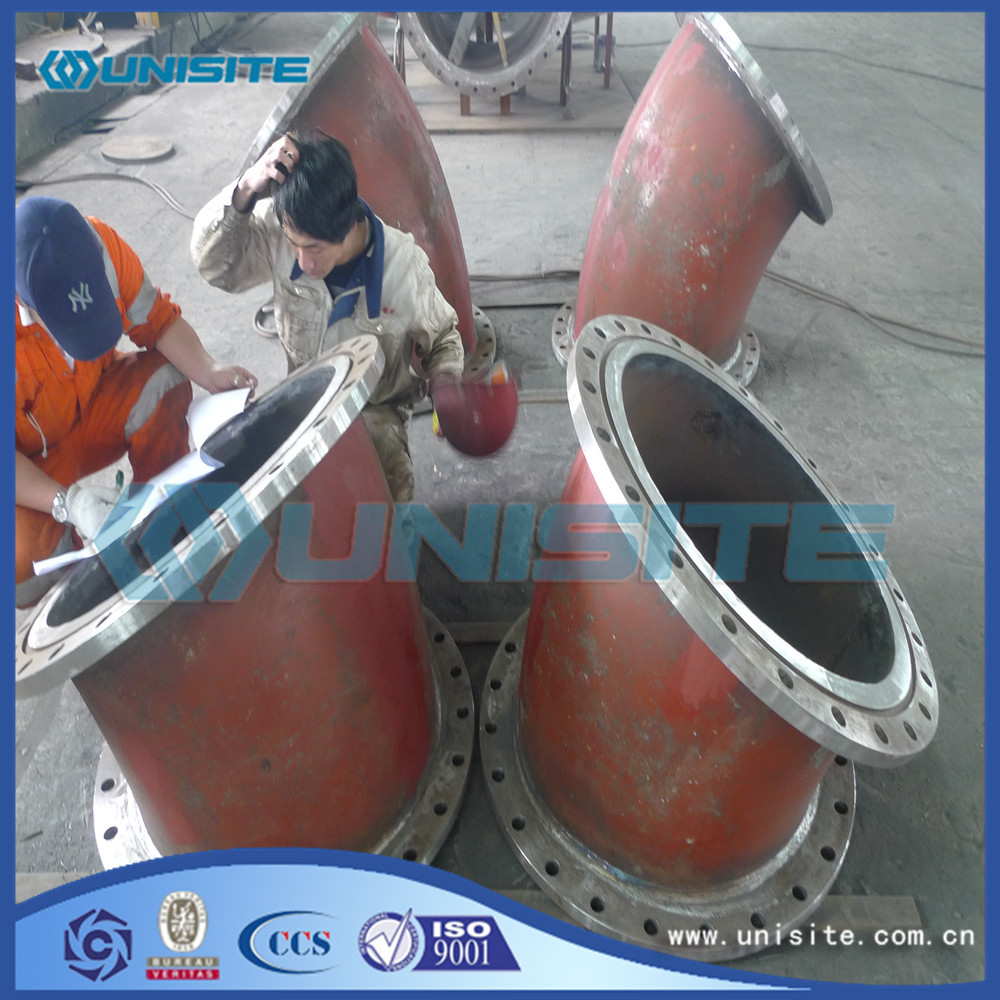

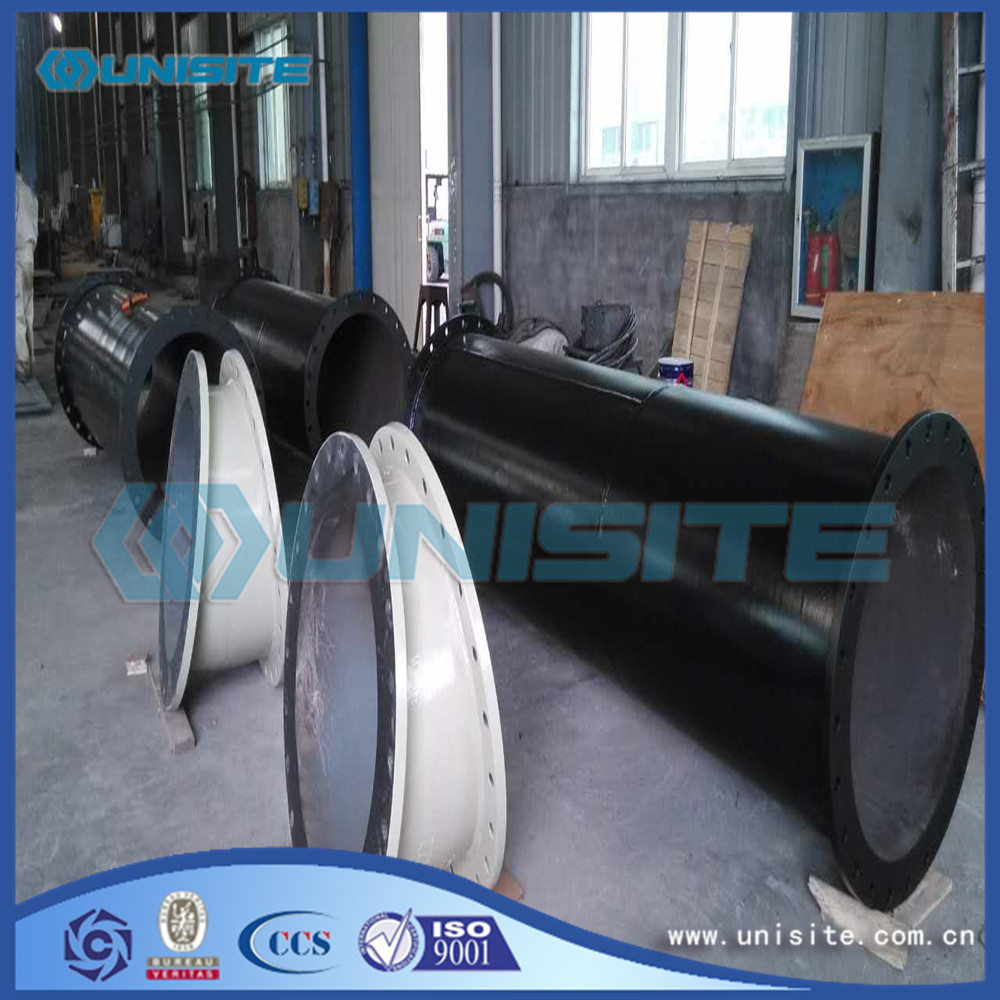

Custom pressed bend pipes

Basic Info

Model No.: USA-077

Product Description

Stamping welding elbow, it is the same material with the tube sheet metal stamping die with a half block ring bend, and then the two half ring elbow for welding. Because of various pipe welding standards are different, usually by the group on the fixed semi-finished products of the factory, on-site construction according to the pipe weld level of welding, therefore, also known as the two halves of the welding elbow.

purpose

Pipe installation of a commonly used in connection with the pipe, connecting the two nominal diameter of the same or different tubes, so that the pipe to make a certain angle turn.

The stamping production efficiency is high, and the operation is convenient, easy to realize mechanization and automation, this is because the stamping die and stamping equipment is to rely on to complete the processing, ordinary press trips as per minute

90 degrees of butt welding of stamping elbow

Up to several tens of times, high-speed pressure to hundreds of times per minute or more, and every time the punch stroke may get a punch.

The stamping generally without cutting scrap generated, material consumption is less, and does not need to other heating equipment, so it is a kind of material saving, energy saving and processing, stamping parts of the cost is low.

The stamping process the size range is larger, more complex shape parts, such as a small clock stopwatch to auto longeron, covering parts, stamping cold material deformation hardening effect and punching strength and stiffness are higher.

The stamping die due to ensure the stamping part dimension and shape precision, and generally does not destroy the stamping parts of the surface quality, and die life is generally longer, so stamping quality stability and interchangeability good, has the characteristic of "identical".

The forming process of stamping elbow is complicated, and it needs to be welded according to different materials and uses, and is gradually formed under certain pressure. Stamping elbow molding need according to a certain process, strictly comply with the corresponding process, otherwise the production of stamping elbow will produce quality problems. According to the need, a circular ring shell can be cut into 90 6 degree elbow or 60 elbow or other specifications of the elbow, the process is applied to the

Any specification of large scale, with the diameter of the elbow and the diameter of the elbow is larger than that of the 1.5D, is an ideal method for the manufacture of large push bends.

This process molding method used in the production of different bends, in different areas to show good use value, so that the process in the production of different bends with good value reflected.

Besides above the general specifications, we can also supply some specific bends and other similar steel structure as clients' requirements.

Package and shipping

Wooden Cases, Wooden Pallet or Neutral Boxes package and container transportation

Photos of our Custom pressed bend pipes

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Pipe Bend > Pressed Bend