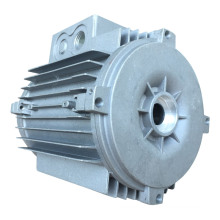

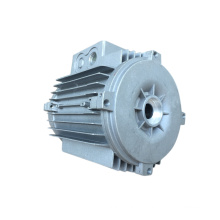

Customized Aluminum Casting Motor Shell Housing

Basic Info

Model No.: OEM Aluminum casting

Product Description

Model NO.: OEM Aluminum Casting Casting Method: Thermal Gravity Casting Application: Auto Parts Material: Aluminium & Aluminum Alloy Surface Roughness: Ra0.1 Certification: SGS, CE, ISO 9001:2000, ISO 9001:2008, AISI, CE, Ieo, SGS Technology: Sand Casting, Strict QC: Reliable with Precision 0.05 Machinig: Tapping, Milling, Grinding OEM and ODM: OEM Motor Shell Housing Delivery Time: 30 Days After Payment Specification: From 0.010kg to 50kgs HS Code: 859862000 Type: Chemical Hardening Sand Sand Core Type: Clay Sand Core Machining: CNC Machining Surface Treatment: Galvanized Standard: ASME Name: Casting Motor Shell Housing Surface Finish: Anodizing, Polishing, Powder Coating etc Size and Length: Sandard or Custom Require Warranty: 20 Years Welcome: OEM and ODM Trademark: XH Origin: Qingdao China Customized Aluminum Casting Motor Shell Housing

1.Material: aluminum. cast iron

2.technology: sand casting + machining

3.Machining; cnc ,tapping, milling, grinding

4.Surface Finish: Anodizing, Polishing, Powder Coating etc

1. About us

Qingdao Xinghe Machinery Ltd. Co., locates in Qingdao, China, is a group of one machinery company and ten of foundries and machining factories. As a professional Machinery company, we have great experience in producing and exporting various OEM casting, Forging parts and Machining Parts base on client's design or sample. Main material includes grey iron, ductile iron, stainless steel, carbon steel, copper and aluminium.

Main products are Pump Parts, motor housing, lathe accessaries, construction machinery, drainage system, automobile industry and so on. Besides, also export the Rigging, Marine, Lifting and Construction Hardware, Chains, Wire Ropes.

2. The process line of production

* Material: Ductile Iron, Carbon Steel, Grey iron, stainless steel, steel, aluminium, brass...

* Sand and investment casting(Precision Casting)are all avalable

* Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF and Solidwork 2008 flow analysis

* Further machining work: Turning and cutting, milling, grinding, drilling, reaming and threading

* Equipment: CNC center, CNC center and lathes.

* Surface finish process: Shot blast, chromate plating, power coated and anodizing

* OEM/ODM parts range: Auto parts, electronic parts, furniture parts, home appliance and other industrial uses

* Process: CAD surface, matel processing, surface plating, QC testing and packaging

* Made according to customers' drawing, sepecification and samples

* Castng capacity: 1000tons/per month

3. Detailed Discriptions:

*Materials:

Aluminium, Brass, Copper, Bronze, Stainless Steel, Gery Iron, Ductile Iron

*Annual Capacity:

10, 000 tons

*MOQ:

50 pieces

*Lead Time:

Discussion with customers

*QC System:

100% inspection before shipment

*Packagings:

1) Polybag and carton, 0.5-20kg/carton,

2) Pallet or container,

3) As per customized specifications.

*Payment Terms:

Negotiable

Contact us if you need more details on Casting Motor Housing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Motor Shell Housing、Aluminum Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Material: aluminum. cast iron

2.technology: sand casting + machining

3.Machining; cnc ,tapping, milling, grinding

4.Surface Finish: Anodizing, Polishing, Powder Coating etc

1. About us

Qingdao Xinghe Machinery Ltd. Co., locates in Qingdao, China, is a group of one machinery company and ten of foundries and machining factories. As a professional Machinery company, we have great experience in producing and exporting various OEM casting, Forging parts and Machining Parts base on client's design or sample. Main material includes grey iron, ductile iron, stainless steel, carbon steel, copper and aluminium.

Main products are Pump Parts, motor housing, lathe accessaries, construction machinery, drainage system, automobile industry and so on. Besides, also export the Rigging, Marine, Lifting and Construction Hardware, Chains, Wire Ropes.

2. The process line of production

* Material: Ductile Iron, Carbon Steel, Grey iron, stainless steel, steel, aluminium, brass...

* Sand and investment casting(Precision Casting)are all avalable

* Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF and Solidwork 2008 flow analysis

* Further machining work: Turning and cutting, milling, grinding, drilling, reaming and threading

* Equipment: CNC center, CNC center and lathes.

* Surface finish process: Shot blast, chromate plating, power coated and anodizing

* OEM/ODM parts range: Auto parts, electronic parts, furniture parts, home appliance and other industrial uses

* Process: CAD surface, matel processing, surface plating, QC testing and packaging

* Made according to customers' drawing, sepecification and samples

* Castng capacity: 1000tons/per month

3. Detailed Discriptions:

*Materials:

Aluminium, Brass, Copper, Bronze, Stainless Steel, Gery Iron, Ductile Iron

*Annual Capacity:

10, 000 tons

*MOQ:

50 pieces

*Lead Time:

Discussion with customers

*QC System:

100% inspection before shipment

*Packagings:

1) Polybag and carton, 0.5-20kg/carton,

2) Pallet or container,

3) As per customized specifications.

*Payment Terms:

Negotiable

| Process | Material | Standard | |||

| Sand casting | Green sand | Grey iron,Duerle iron,Malleable iron, | ASTM,BS,JIS,DIN etc | ||

| Furan resin | Stainless steel, Carbon steel, | ||||

| Gold harden | Aluminum,Brass,Bronze | ||||

| Investment casting | Sodium silicone | Stainless steel, Carbon steel,Brass, | |||

| Silica sol | Bronze,Aluminum,Special alloy steel | ||||

| Forging | Hammer forging | Stainless steel, Carbon steel,Brass, | |||

| Die forging | Alloy steel,Aluminum | ||||

| Roll forging | |||||

| Stamping Machining | Stamping | All metel material | |||

| Machining | |||||

Contact us if you need more details on Casting Motor Housing. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Motor Shell Housing、Aluminum Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Motor Frame

Premium Related Products

Other Products

Hot Products

New design fashion low price door handles with locksNew arrival 2016 custom Aluminum Die Casting Gear HousingAluminum Alloy casted LED Light EnclosureAntenna Mountanchor rodsDrain Parts can be used for bathroom sink and floorAluminum and Zinc Die Casting partDie Casting aluminum Enclosure/die casting moldCooling block2015 made in China customized die casting aluminum wheelCE certificated powder coating Electrical Cabinet/sheet metal formingPlastic Float BallSteel hanger, apron rack,Medical hangersFull suspection steel belt wheel 2015Toughened glassRotational Molded Boat