scan tool plastic parts Chinese manufacturer with high quality

Basic Info

Model No.: Customized

Product Description

Buying Guides How to get satisfied quotation quickly from us? When you want to ask for mold price and unit part price, please do as these three steps. 1) Please try to tell us which grade would you want according to following form:

2) Tell us: Do you want mold only or want mold and plastic product? 3) Tell us: Plastic type and QTY you want? 4) Send us the product drawing (or sample, or pictures with ruler ) then. 5) Feel free to contact Sandra( Skype:wtmold-marketing01). Product Description Specifications 1.Product name: scan tool Plastic Parts Chinese manufacturer with high quality 2.Grade:C 3.Save mold cost: 25% 4. Sample:free(delivery time:within one week)

5.Mold check: by QC checked before shipping, with the sample report. 6.Your logo or other information could be printed for advertisement. 7.Other colors or sizes may be available.Welcome to call for more details.

Detail product pictures

Project process

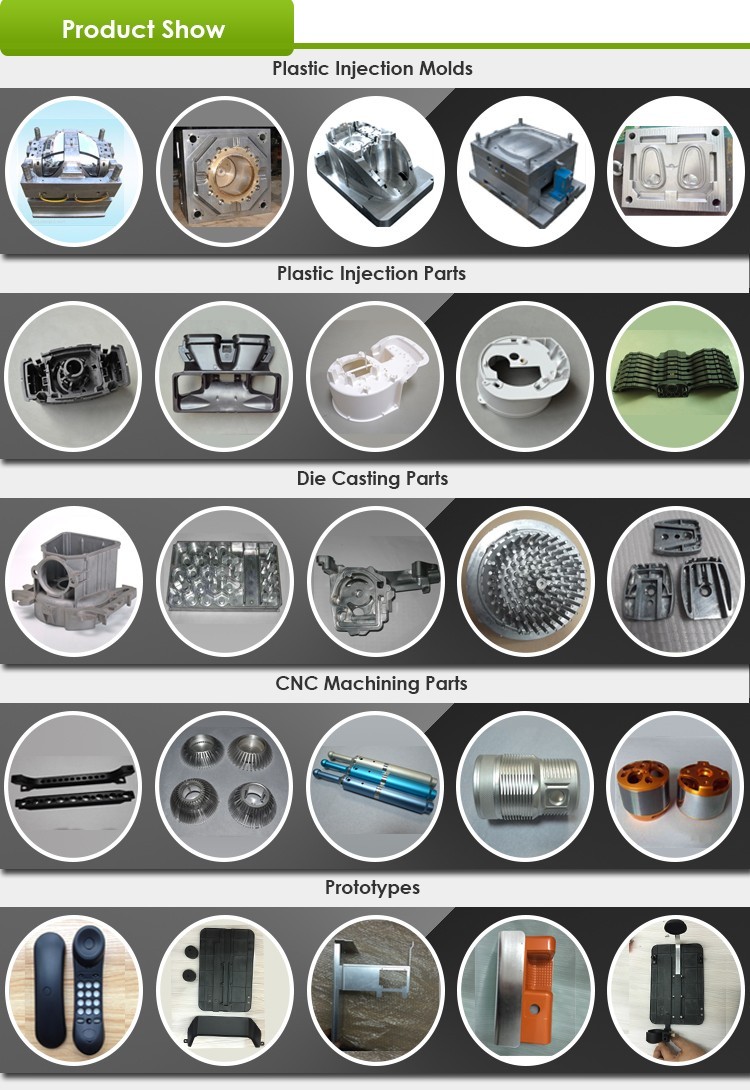

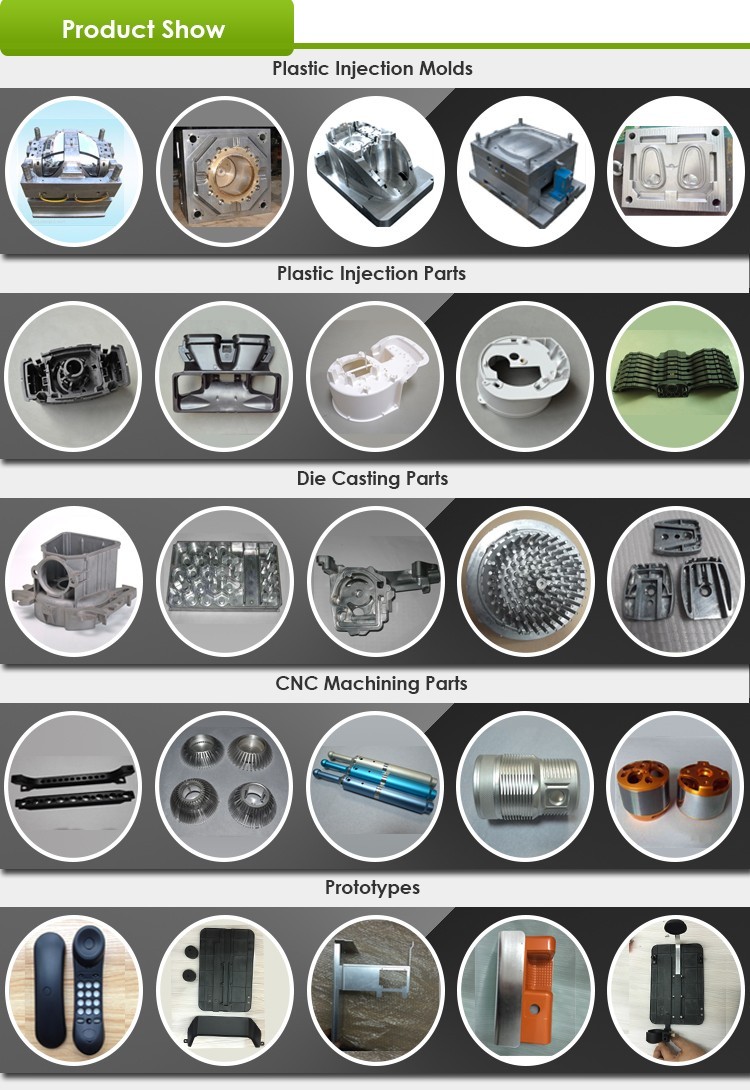

Project process  Our Services Located in Shenzhen where is Chinese mold manufacturing center with the best quality and mold technology, Shenzhen WT hardware and plastics Limited has ten-years rich experience in making customized mold and products for customers all over the world.And 80% of customers are from USA, EU, CIS, South America and other Asia. Our main service: 1. Plastic injection mold and die-casting mould. 2. Plastic part and Die Casting part. 3. Prototype making. 4. Machining Parts 5. Assemble Keep secret to your idea and your design Our advantages: 1. Manufacturing and Exporting Experience for about 10 Years. ISO 9001 approved & TS16949 approved. 2. Professional Sales and Design Team, Mold Maker Engineers. (Good English capabilities and communication skills. To provide professional high-efficiency service to you.) 3. In Time Service. ( In-time response on letters, telephone calls or fax; In-time supply the quotation and mould designs; In-time communication on the technical and cooperation points; In-time mould test and sample delivery; In-time mould and product delivery. We deliver the goods timely according to your requirements, and never receive any complaints about our late delivery.) 4. Competitive Price. (Our mold price is lower 30% than other suppliers with the same good quality, just because we are manufactory, we are the source. a discount will offer if you place a large order. And if the order comes to a certain quantity, we will return the molds cost to you.) 5. Strict Quality Control.(Professional QC and R&D teams control the quality strictly to assure high quality.Every step of our production is carefully monitored through QC;Most our products have passed the Walmart, Homedepot, CE and CCC inspection(China Compulsory Certification);Rich experience in product testing, such as ASTM, CPSIA, EN71, BV testing, FDA, RoHS.)

Our Services Located in Shenzhen where is Chinese mold manufacturing center with the best quality and mold technology, Shenzhen WT hardware and plastics Limited has ten-years rich experience in making customized mold and products for customers all over the world.And 80% of customers are from USA, EU, CIS, South America and other Asia. Our main service: 1. Plastic injection mold and die-casting mould. 2. Plastic part and Die Casting part. 3. Prototype making. 4. Machining Parts 5. Assemble Keep secret to your idea and your design Our advantages: 1. Manufacturing and Exporting Experience for about 10 Years. ISO 9001 approved & TS16949 approved. 2. Professional Sales and Design Team, Mold Maker Engineers. (Good English capabilities and communication skills. To provide professional high-efficiency service to you.) 3. In Time Service. ( In-time response on letters, telephone calls or fax; In-time supply the quotation and mould designs; In-time communication on the technical and cooperation points; In-time mould test and sample delivery; In-time mould and product delivery. We deliver the goods timely according to your requirements, and never receive any complaints about our late delivery.) 4. Competitive Price. (Our mold price is lower 30% than other suppliers with the same good quality, just because we are manufactory, we are the source. a discount will offer if you place a large order. And if the order comes to a certain quantity, we will return the molds cost to you.) 5. Strict Quality Control.(Professional QC and R&D teams control the quality strictly to assure high quality.Every step of our production is carefully monitored through QC;Most our products have passed the Walmart, Homedepot, CE and CCC inspection(China Compulsory Certification);Rich experience in product testing, such as ASTM, CPSIA, EN71, BV testing, FDA, RoHS.)  FAQ 1) Are you a trading company or manufacturer? We're a manufacturer. 2) How many molds can you build per year?

FAQ 1) Are you a trading company or manufacturer? We're a manufacturer. 2) How many molds can you build per year?

We can build 400-500 sets of Injection Molds per year.

3) When did you start to export molds to USA and Europe?

We had business with them for 8 years. So we know their standard very well.

4)Where are your molds exported?

80 percent of the molds we built are exported to USA, Europe, Japan. 20% are exported to other countries. 5) Can you make insert mold?

Yes, we can, we are good at insert molds too. we have more experience in insert molds. 6) Can you make multi-cavity mold?

Yes, we built some of molds with 16,32,64 cavities. 7)Can you make double color Injection Mold and over mold? Yes, we can. 8)How long is the lead-time for mold? It all depends on the mold’s size and complexity. Normally, the lead time is 25—35days. If the molds are very simple and not big size, we can work out within 15 days.And we can provide samples free for you! 9) How about your terms of payment?

For new mold, 40% deposit, 40% on first short, 20% after sample approved (before delivery or 1st production). 10) How do you pack the mold?

We pack it strictly in accordance with export regulation.

11) Can you arrange shipment?

Yes,we can. We have shipping Department to handle it. Contact Infornmation Dear Friend, Many thanks for your interest in our product and service, what can I do for you ? Please do feel free to contact me for more information and details, I'm glad to consult and cooperate with you. Contact us if you need more details on Scan Tool. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Parts、Plastic Parts Chinese Manufacture. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Scan Tool. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Parts、Plastic Parts Chinese Manufacture. If these products fail to match your need, please contact us and we would like to provide relevant information.

| A Grade | B Grade | C Grade | D Grade | |

| Mold baseStandard | HASCO/DME | LKM | LKM | Chinese Local |

| Cavity steel | H13,2344,2343,8407 Heat Hard steel | 718, 738, P20HH, NAK80 | Local P20, WY718 | Alunimun, S50C |

| Standard | HASCO, DME | LKM | Chinese Local | / |

| Mold life | >500,000~3000,000 | 300,000~500,000 | 100,000~300,000 | >10000 or only for prototype |

| Runner | Hot runner, cold runner | Hot runner, cold runner | Cold runner | Cold runner |

| Mold price | Most expensive | Expensive | Cost-effective | Cheapest |

5.Mold check: by QC checked before shipping, with the sample report. 6.Your logo or other information could be printed for advertisement. 7.Other colors or sizes may be available.Welcome to call for more details.

| 2D drawing soft | Autocad |

2D drawing format | dwg,dxf, pdf |

| 3D drawing soft | Pro-e, UG, Solidwork, MasterCAM,Catia |

| 3D drawing format | igs,iges,stp,step,sldprt,etc |

| Mold base standard | LKM,HASCO,DME |

| Companets standard | LKM, HASCO,DME,DADIO, Robordin |

| Mold steel | P20,718,738,H13,1.2312,1.2344,8407,SKD61,Nak80,S136, etc |

| Hot Runner Brand | YUDO, Mold Master, Mastip, DME, Thermplay,Gunter,Hot tip, |

| Mold Surface treadment | MT texture, YS texture, VDI texture, Polish, Mirror Polish, plating etc, |

| Mold Size | 150*150mm |

| Mold Life | 10,000 shots |

| Shipping method | Express, by air, by sea. |

Project process

Project process  Our Services Located in Shenzhen where is Chinese mold manufacturing center with the best quality and mold technology, Shenzhen WT hardware and plastics Limited has ten-years rich experience in making customized mold and products for customers all over the world.And 80% of customers are from USA, EU, CIS, South America and other Asia. Our main service: 1. Plastic injection mold and die-casting mould. 2. Plastic part and Die Casting part. 3. Prototype making. 4. Machining Parts 5. Assemble Keep secret to your idea and your design Our advantages: 1. Manufacturing and Exporting Experience for about 10 Years. ISO 9001 approved & TS16949 approved. 2. Professional Sales and Design Team, Mold Maker Engineers. (Good English capabilities and communication skills. To provide professional high-efficiency service to you.) 3. In Time Service. ( In-time response on letters, telephone calls or fax; In-time supply the quotation and mould designs; In-time communication on the technical and cooperation points; In-time mould test and sample delivery; In-time mould and product delivery. We deliver the goods timely according to your requirements, and never receive any complaints about our late delivery.) 4. Competitive Price. (Our mold price is lower 30% than other suppliers with the same good quality, just because we are manufactory, we are the source. a discount will offer if you place a large order. And if the order comes to a certain quantity, we will return the molds cost to you.) 5. Strict Quality Control.(Professional QC and R&D teams control the quality strictly to assure high quality.Every step of our production is carefully monitored through QC;Most our products have passed the Walmart, Homedepot, CE and CCC inspection(China Compulsory Certification);Rich experience in product testing, such as ASTM, CPSIA, EN71, BV testing, FDA, RoHS.)

Our Services Located in Shenzhen where is Chinese mold manufacturing center with the best quality and mold technology, Shenzhen WT hardware and plastics Limited has ten-years rich experience in making customized mold and products for customers all over the world.And 80% of customers are from USA, EU, CIS, South America and other Asia. Our main service: 1. Plastic injection mold and die-casting mould. 2. Plastic part and Die Casting part. 3. Prototype making. 4. Machining Parts 5. Assemble Keep secret to your idea and your design Our advantages: 1. Manufacturing and Exporting Experience for about 10 Years. ISO 9001 approved & TS16949 approved. 2. Professional Sales and Design Team, Mold Maker Engineers. (Good English capabilities and communication skills. To provide professional high-efficiency service to you.) 3. In Time Service. ( In-time response on letters, telephone calls or fax; In-time supply the quotation and mould designs; In-time communication on the technical and cooperation points; In-time mould test and sample delivery; In-time mould and product delivery. We deliver the goods timely according to your requirements, and never receive any complaints about our late delivery.) 4. Competitive Price. (Our mold price is lower 30% than other suppliers with the same good quality, just because we are manufactory, we are the source. a discount will offer if you place a large order. And if the order comes to a certain quantity, we will return the molds cost to you.) 5. Strict Quality Control.(Professional QC and R&D teams control the quality strictly to assure high quality.Every step of our production is carefully monitored through QC;Most our products have passed the Walmart, Homedepot, CE and CCC inspection(China Compulsory Certification);Rich experience in product testing, such as ASTM, CPSIA, EN71, BV testing, FDA, RoHS.)  FAQ 1) Are you a trading company or manufacturer? We're a manufacturer. 2) How many molds can you build per year?

FAQ 1) Are you a trading company or manufacturer? We're a manufacturer. 2) How many molds can you build per year?We can build 400-500 sets of Injection Molds per year.

3) When did you start to export molds to USA and Europe?

We had business with them for 8 years. So we know their standard very well.

4)Where are your molds exported?

80 percent of the molds we built are exported to USA, Europe, Japan. 20% are exported to other countries. 5) Can you make insert mold?

Yes, we can, we are good at insert molds too. we have more experience in insert molds. 6) Can you make multi-cavity mold?

Yes, we built some of molds with 16,32,64 cavities. 7)Can you make double color Injection Mold and over mold? Yes, we can. 8)How long is the lead-time for mold? It all depends on the mold’s size and complexity. Normally, the lead time is 25—35days. If the molds are very simple and not big size, we can work out within 15 days.And we can provide samples free for you! 9) How about your terms of payment?

For new mold, 40% deposit, 40% on first short, 20% after sample approved (before delivery or 1st production). 10) How do you pack the mold?

We pack it strictly in accordance with export regulation.

11) Can you arrange shipment?

Yes,we can. We have shipping Department to handle it. Contact Infornmation Dear Friend, Many thanks for your interest in our product and service, what can I do for you ? Please do feel free to contact me for more information and details, I'm glad to consult and cooperate with you.

Contact us if you need more details on Scan Tool. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Parts、Plastic Parts Chinese Manufacture. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Scan Tool. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Parts、Plastic Parts Chinese Manufacture. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Molding Part

Premium Related Products

Other Products

Hot Products

New design fashion low price door handles with locksNew arrival 2016 custom Aluminum Die Casting Gear HousingAluminum Alloy casted LED Light EnclosureAntenna Mountanchor rodsDrain Parts can be used for bathroom sink and floorAluminum and Zinc Die Casting partDie Casting aluminum Enclosure/die casting moldCooling block2015 made in China customized die casting aluminum wheelCE certificated powder coating Electrical Cabinet/sheet metal formingPlastic Float BallSteel hanger, apron rack,Medical hangersFull suspection steel belt wheel 2015Toughened glassRotational Molded Boat