H frame Hydraulic Press Machine Deep Drawing 400T

Basic Info

Model No.: Yz27

Product Description

Auto stampings, as the name implies, are metal stampings that make up automotive parts. In the automotive Stamping parts, some of them are directly turned into Auto Parts after being stamped, and the other part is subjected to welding, machining, or painting after being stamped to become auto parts. There are many kinds of automobile stamping parts, oil press machine,such as automobile shock absorber stamping spring tray, spring seat, spring bracket, end cover, cover, compression valve cover, compression valve sleeve, oil seal seat, bottom cover, dust cover, impeller, oil Tubes, ears, brackets, etc. are all automotive stampings.

The oli press (a type of hydraulic press) is a working medium through a special hydraulic oil. The hydraulic pump is used as a power source, and the hydraulic oil is used to enter the cylinder/piston through the hydraulic line by the force of the pump. Then there are several cylinders/pistons. The seals that match each other, the seals at different positions are different, but they all play the role of sealing, so that the hydraulic oil can not leak. Finally, through the one-way valve, the hydraulic oil is circulated in the fuel tank to make the cylinder/piston cycle work to complete a certain mechanical action as a kind of machine for productivity.

Features

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: Forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

Parameters

| Mold | unit | 63T | 100T | 160T | 200T | 250T | 315T | 500T | 630T | 800T | 1000T | 1250T | |

| Main cylinder (slider) process specs | Max.press force | KN | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 30000 |

| Max.return force | KN | 150 | 100 | 315 | 450 | 540 | 630 | 1000 | 1000 | 1200 | 1600 | 2100 | |

| Down speed | mm/s | 100 | 100 | 160 | 160 | 140 | 140 | 140 | 250 | 200 | 150 | 150 | |

| Slow speed | mm/s | 20 | 15 | 15 | 15 | 12 | 15 | 15 | 15 | 15 | 15 | 12 | |

| The proportion of floating pressing speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Press speed | mm/s | 10 | 10 | 10 | 10 | 7 | 8 | 8 | 8 | 8 | 8 | 6 | |

| Return speed | mm/s | 120 | 120 | 120 | 110 | 95 | 100 | 100 | 150 | 150 | 120 | 120 | |

| Max.stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | |

| Top cylinder process specs | Max.ejection force | KN | 280 | 440 | 450 | 900 | 900 | 1250 | 1800 | 2200 | 2200 | 2750 | 10000 |

| Max.pull force | KN | 280 | 360 | 450 | 750 | 750 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Eject speed | mm/s | 80 | 34 | 65 | 55 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Floating speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Return speed | mm/s | 80 | 42 | 95 | 70 | 70 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Upper center cylinder process specs | Max.press force | KN | 60 | 60 | 60 | 125 | 150 | 125 | 200 | 200 | 240 | 240 | 500 |

| Max.return force | KN | 30 | 30 | 30 | 76 | 76 | 76 | 130 | 130 | 140 | 140 | 200 | |

| Max.stroke | mm | 30 | 30 | 30 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 | |

| Under center cylinder process specs | Max.press force | KN | 70 | 70 | 125 | 160 | 160 | 200 | 200 | 300 | 300 | 300 | 1000 |

| Max.return force | KN | 40 | 40 | 75 | 100 | 100 | 100 | 100 | 200 | 200 | 200 | 260 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Upper floating cylinder process | Max.press force | KN | 120 | 120 | 130 | 250 | 250 | 300 | 400 | 400 | 480 | 480 | 1000 |

| Max.return force | KN | 60 | 60 | 65 | 150 | 150 | 160 | 200 | 200 | 240 | 240 | 250 | |

| Max.stroke | mm | 45 | 45 | 50 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 70 | |

| Effective worktable size | L-R | mm | 580 | 720 | 780 | 1000 | 1000 | 1000 | 1200 | 1320 | 1400 | 1600 | 2400 |

| F-B | mm | 490 | 580 | 640 | 940 | 940 | 960 | 1140 | 1200 | 1200 | 1350 | 1460 | |

| Max.pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max.filling height | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | |

| Main motor power | KW | 7.5 | 11.5 | 18.5 | 22 | 22 | 30 | 48 | 67 | 82 | 100 | 100 | |

Workshop

Packaging and delivery

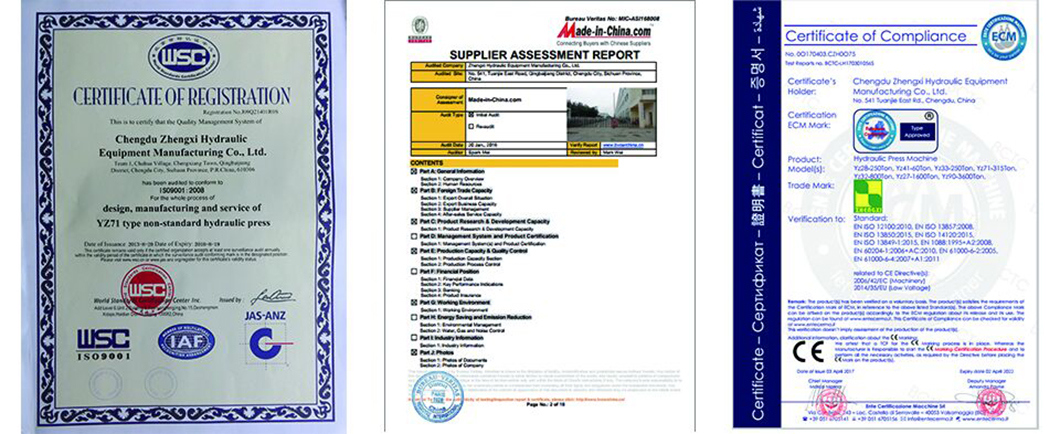

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : H Type Hydraulic Press > Car Interior Decoration Parts